Fine Beautiful Info About What Happens If Insulation Resistance Is Too Low

Insulation Resistance Part 1 Why Do It? YouTube

Insulation Resistance

1. Why Insulation Matters

Think of electrical insulation as a superhero, silently protecting you and your appliances from dangerous electrical leaks. It's the unsung hero ensuring electricity flows where it should — through the wires, powering your gadgets — and not straying into places it shouldn't, like, say, you! Insulation resistance is simply a measure of how well this superhero is doing its job. It tells us how effective the insulation is at preventing current from leaking.

Now, before your eyes glaze over at the mention of 'resistance,' just picture it like this: imagine trying to walk through a thick, sticky swamp. The swamp is the insulation, and your effort to move is the current. Good insulation is a super sticky, super thick swamp, making it nearly impossible for current to get through. Bad insulation? More like a slightly damp meadow. Easy to stroll right through, but not exactly ideal when you're trying to keep electricity contained. So, resistance essentially measures how difficult the insulation makes it for electricity to pass where it shouldn't.

This resistance is measured in megaohms (M). The higher the megaohm value, the better the insulation is performing. A high value indicates that the insulation is doing a fantastic job of resisting current leakage. Conversely, a low megaohm value raises red flags, suggesting that the insulation is compromised and needs attention.

We rely on insulation every single day, from the wiring in our homes to the appliances we use. Understanding its role and the importance of insulation resistance helps us appreciate its contribution to our safety and the efficient operation of electrical systems. In essence, proper insulation safeguards against electric shock, prevents wasted energy, and protects our valuable electrical equipment.

The Danger Zone

2. The Ripple Effect of Weak Insulation

Alright, so your insulation resistance is low. Think of it like your car's tires slowly deflating. You might not notice it immediately, but gradually, things start to get well, inefficient and potentially dangerous. A low insulation resistance means current is leaking, and that leakage can cause a whole host of problems. Lets break it down.

Firstly, you're looking at increased energy consumption. That escaping current isn't doing any work; its just being wasted, like throwing money into a furnace. Your electricity bill might start creeping up, even though your usage habits haven't changed. It's like constantly having a small appliance running in the background, except it's not an appliance, it's just wasted electricity.

Secondly, and much more seriously, is the increased risk of electric shock. That leaking current can find its way to metal surfaces or, worse, to you. Contact with a faulty appliance or wiring with low insulation resistance can result in a painful shock, and in severe cases, can be fatal. It's like playing Russian roulette with your home's electrical system; not exactly a game you want to win.

Finally, low insulation resistance leads to equipment damage and shortened lifespan. The leaking current generates heat, which can degrade the insulation further, creating a vicious cycle. This can cause components to overheat, leading to premature failure of your appliances, motors, and other electrical equipment. Its like running an engine with low oil; eventually, something is going to seize up.

Insulation Resistance Test Low Reading At Andrea Kendal Blog

Pinpointing the Culprit

3. Why is my insulation failing?

So, what causes this insulation superhero to lose its powers? Several factors can contribute to low insulation resistance. Moisture is a big one. Think of leaving bread out in the rain; it becomes soggy and loses its structure. Similarly, moisture seeping into insulation reduces its resistance, providing an easier path for current to leak. High humidity, water leaks, and condensation are all enemies of good insulation.

Another common culprit is contamination. Dust, dirt, oil, chemicals — all sorts of grime can accumulate on insulation, creating conductive paths that lower its resistance. It's like coating your perfectly clean windshield with mud; visibility (or, in this case, insulation performance) plummets.

Age and wear and tear also play a significant role. Over time, insulation degrades naturally due to heat, vibration, and electrical stress. It's like a rubber band that loses its elasticity with age; it becomes brittle and easily snaps. Similarly, old or damaged insulation loses its ability to effectively block current leakage.

Physical damage, such as cuts, abrasions, or punctures, can directly compromise the integrity of the insulation. Even seemingly minor damage can create weak points where current can easily leak. Think of it as a tiny hole in a dam; it may seem insignificant at first, but it can quickly widen and lead to a catastrophic breach. Rodents, improper installation, or accidental impacts are common sources of physical damage.

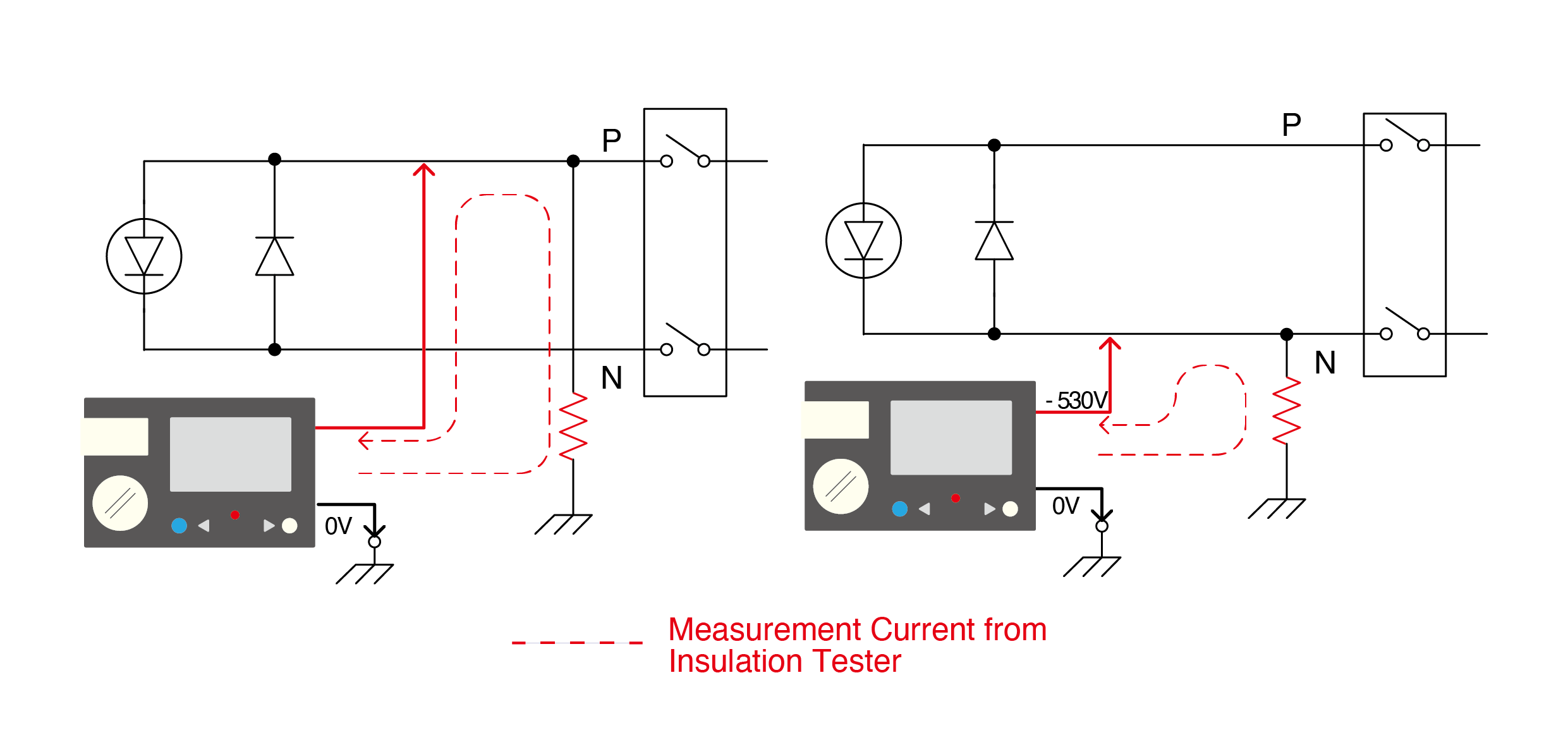

Insulation Resistance Measurement For The Safety Of Solar PV Systems

Testing, Testing

4. Keeping Tabs on Your Electrical System's Health

Fortunately, you don't have to be an electrician to be aware of potential insulation problems. While professional testing is always recommended, understanding the basics can empower you to be proactive about your electrical safety. The most common tool for measuring insulation resistance is a megohmmeter, often called a "megger." This device applies a high DC voltage to the insulation and measures the resulting current leakage.

It's important to note that testing should always be performed by a qualified electrician. Working with electricity can be dangerous, and proper safety procedures must be followed. They'll know how to safely disconnect power to the circuit or equipment being tested and interpret the readings correctly. They will also need to wear the appropriate personal protective equipment (PPE), such as insulated gloves and eye protection.

While DIY testing might seem tempting, leave it to the pros. They can identify potential issues you might miss and ensure that any necessary repairs are done safely and correctly. The cost of professional testing is a small price to pay compared to the potential risks of electrical accidents.

Regular insulation resistance testing is a proactive measure that can help prevent electrical problems before they escalate. Think of it as a routine check-up for your electrical system, ensuring that everything is running smoothly and safely. Schedule periodic inspections, especially for older homes or buildings, or if you suspect any electrical issues.

Insulation Resistance Test On Busbar At Elissa Ruben Blog

Taking Action

5. Restoring Your Insulation's Shield

So, the test results are in, and your insulation resistance is below acceptable levels. Don't panic! This doesn't necessarily mean you need to rip out all your wiring. The best course of action depends on the cause and severity of the problem. Often, cleaning and drying the affected area can restore insulation resistance. Removing contaminants and moisture can significantly improve its performance.

If cleaning isn't enough, repairs or replacement may be necessary. Minor damage to insulation can sometimes be repaired with specialized insulating tapes or compounds. However, for more extensive damage, complete replacement of the affected wiring or equipment is the safest and most reliable solution. Its better to be safe than sorry.

The most crucial step is to involve a qualified electrician. They can properly diagnose the problem, recommend the appropriate solution, and perform the necessary repairs or replacements safely and effectively. Attempting to fix electrical problems yourself can be dangerous and may void warranties on your equipment. Consider it a small investment for piece of mind and safety.

After repairs or replacements are complete, it's essential to retest the insulation resistance to ensure that it meets acceptable standards. This confirms that the problem has been resolved and that your electrical system is operating safely and efficiently. Think of it as a final exam to make sure all the remedial work was worthwhile.

Resistance Electricity

Frequently Asked Questions

6. Your Insulation Resistance Questions Answered

Let's address some common questions about insulation resistance to further clarify the topic.

7. Q

A: The frequency of testing depends on several factors, including the age of your home or building, the type of electrical equipment, and the environmental conditions. As a general guideline, it's recommended to have insulation resistance tested every 3 to 5 years. However, if you notice any signs of electrical problems, such as flickering lights, tripping breakers, or unusual odors, you should schedule a test immediately.

8. Q

A: While a megohmmeter provides the most accurate measurement, there are some telltale signs that can indicate low insulation resistance. These include increased energy bills, frequent tripping of circuit breakers, warm or vibrating electrical outlets, and a burning smell coming from electrical equipment. If you notice any of these signs, it's crucial to have your electrical system inspected by a qualified electrician.

9. Q

A: Yes, low insulation resistance can definitely increase the risk of fire. Leaking current generates heat, which can ignite flammable materials nearby. This is especially dangerous in areas with combustible dust, paper, or other flammable substances. Therefore, it's crucial to address low insulation resistance promptly to prevent potential fire hazards.

10. Q

A: A good insulation resistance value generally depends on the voltage rating of the equipment or wiring being tested. A common rule of thumb is at least 1 megaohm per 1000 volts. For example, a 480-volt motor should ideally have an insulation resistance of at least 0.48 megaohms. However, it's always best to refer to the manufacturer's specifications or consult with a qualified electrician to determine the appropriate insulation resistance value for your specific equipment.